- By Digilatics

- Uncategorized

- 0 Comment

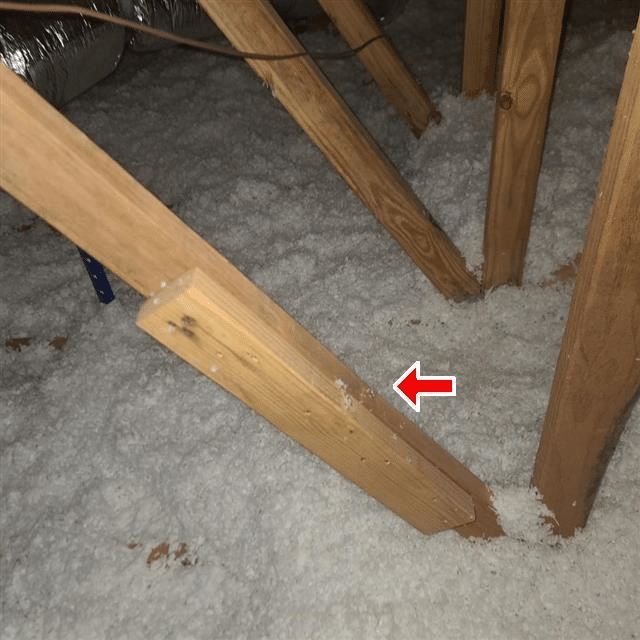

Inspection of engineered trusses is best done during the pre-drywall inspection. They are completely exposed and are also readily accessible for repair. Most damage to engineered attic trusses happens when the trusses are either dumped off the truck or hoisted into the air by a crane. A thorough inspection is recommended because odds are some day your client will want to sell the house. Home inspectors may find the damaged truss and then your client will be on the hook to make repairs. Engineers are expensive and the builder’s warranty is long gone as well as the builder.

What to look for:

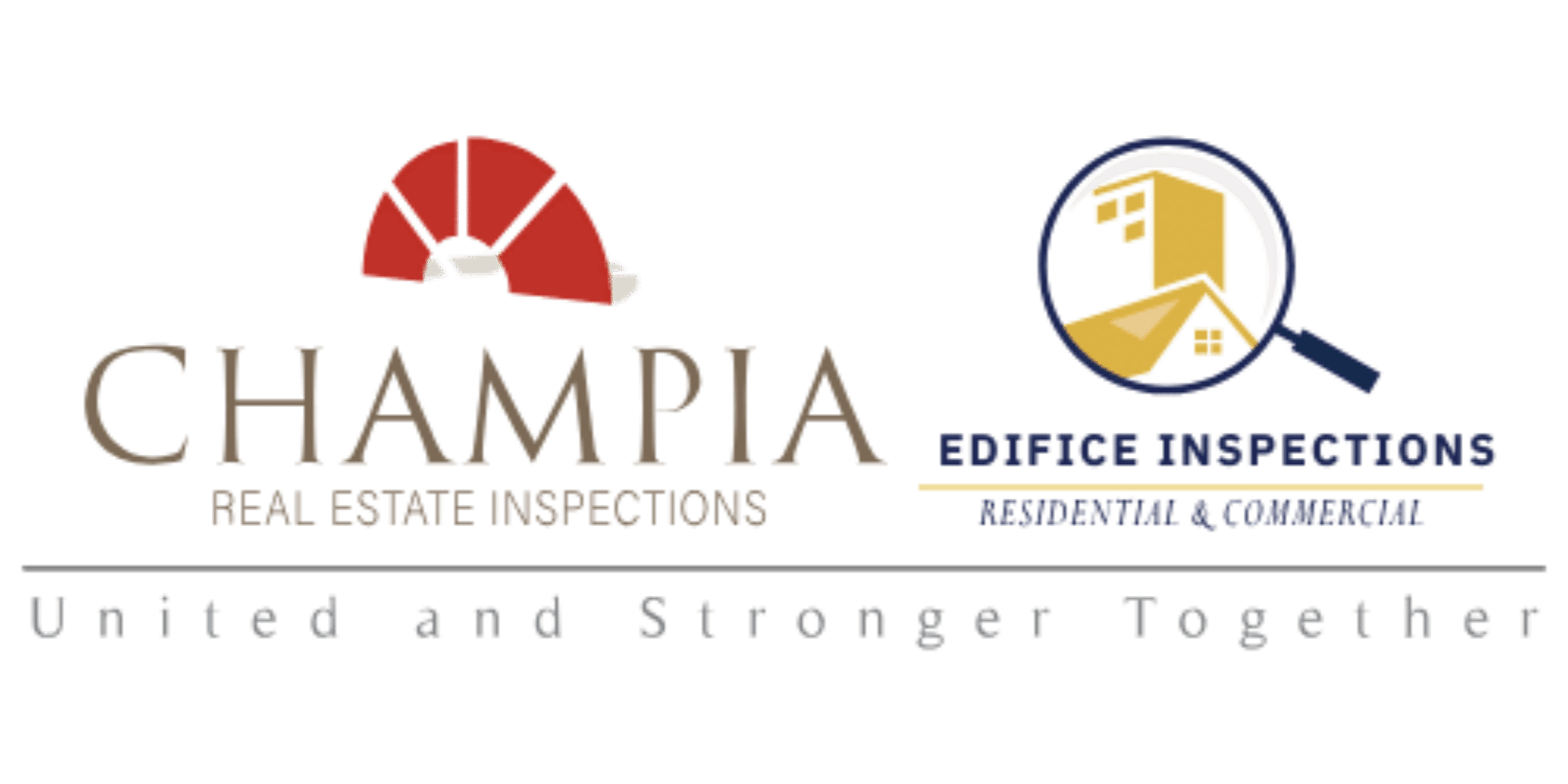

When inspecting attics you want to look for boards that were added after the truss left the plant. Usually a repair will have two boards sistered on both sides of the broken or missing board.

This is a good example where the middle spar was broken off. They added the two 2 x 4 on either side of the damage to allow the rafter to be craned into place.

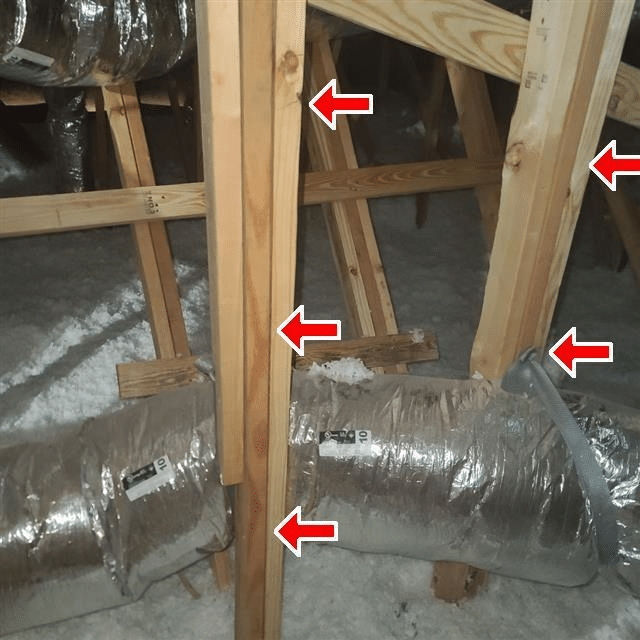

This repair looks innocuous but you want to ask the builder why is this board here. According to code engineered product repairs whether they are attic trusses, floor trusses, or floor beams require a repair

letter from the manufacturer or a licensed engineer.

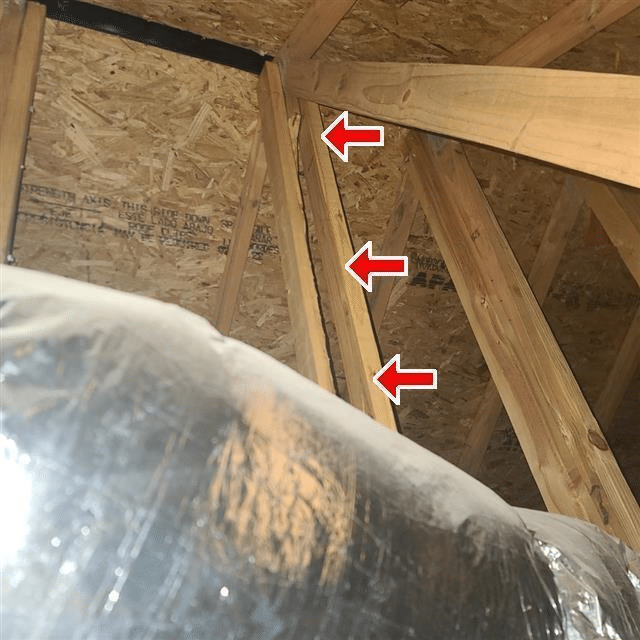

Below is a repair letter example. It will need to have the engineers stamp to validate that it was reviewed by a licensed engineer. The repair letter will describe the materials, fasteners, and the pattern the fasteners are installed.

Repairs at joints usually include large pieces of plywood. See the picture below for what this repair looked like. This was done very well by the builder.

Some people will ask why this was not caught by the county. It is simply a matter of time. The highly qualified county inspector may have numerous stops and hundreds of miles to cover in a day. So sometimes they miss the fine details during their inspection. Your home inspector can spend the time to find the anomalies in the home and shed light on them.